Here we come to a successful end of the advanced research nwt 7 "Textile engineering and Cable harnesses" program from March 29, 2021 to March 31, 2021 hosted by the Université de Liège along with the industrial partners GDTech and Centexbel.

The training was initially planned to be hosted in a hybrid format with an onsite arrangement in the beautiful Sart-Tilman campus of the university for the local participants observing strict rules of pandemic. Later on, due to certain updates in the regulations from Belgian Authorities, the program was conducted fully online.

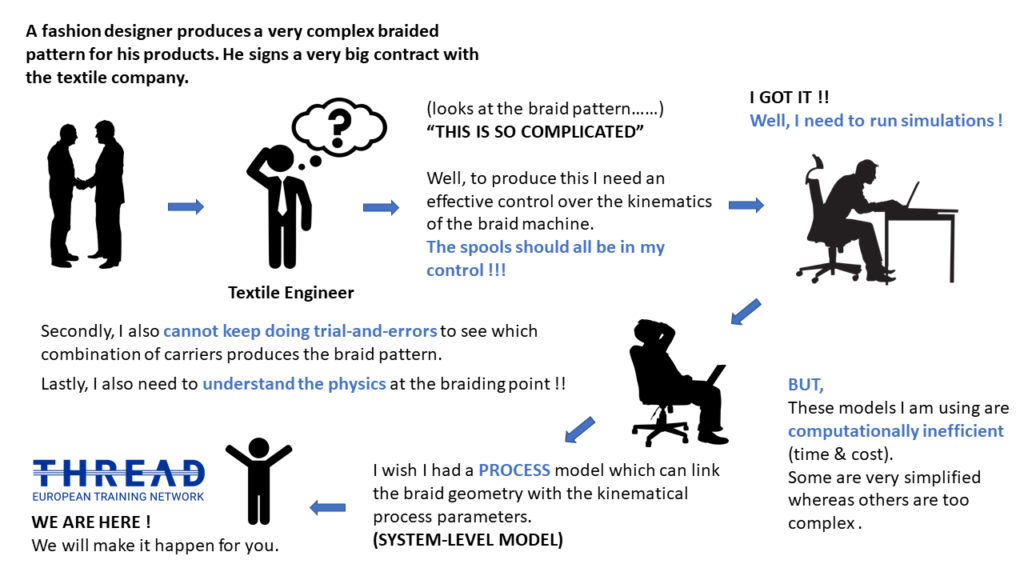

The training commenced in the morning with an introduction to textile engineering by Baptiste Herlin who has a wealth of industrial experience in advanced composites and textile technology. His session focused on the various textile manufacturing processes (braiding, weaving, knitting etc.) and the sophisticated machines along with the diverse range of applications which were very interesting for a layman to dive into the world of textile engineering. This was followed by Olivier Brüls taking us deeper into braiding technology and its modelling by introducing the technical aspects in 2D Maypole braiding, machine components, common types of braids and processes along with a detailed overview of the mechanics of braiding process, geometrical models of braid structures, FE as well as the popular "digital element approach" and process kinematics.

Moving ahead, we had a virtual tour of the Centexbel textile research centre with videos to visualize the different procedures of testing and manufacturing with the advanced machines used, and indeed it was an immersive experience for all the participants. The tour was valuable in having a practical overview to the theoretical aspects of textile engineering learnt in the previous sessions. This was followed by an hour of brain-storming group exercise sessions in braiding technology. The first day was indeed an exciting start to the training program.

We continued the session on the second day with an engaging presentation by Dr. Michael Bruyneel from GDTech on numerical simulation of slender structures in the industry. He gave us an interesting insight into the diverse applications of projects at GDTech such as inflatable structures for space applications, braiding composites (VIBRA), airship designs, pipe models and much more! This session was indeed a rich experience for all of us due to the vast research experience that he shared with us in the session. After a refreshing lunch break, we resumed back to complete the exercise sessions on braiding models. These exercises comprised of models to predict the yarn trajectory on complex mandrel shapes, along with incorporating effects such as yarn crimp in the models, with theoretical brain-storming questions which initiated quality group discussions.

The third day was equally engrossing when Olivier Brüls presented an introduction to the technological aspects of cable harnesses and its applications in the morning session. It enhanced a deeper understanding of mechanical and electrical cables in various contexts of applications and wiring harnesses. In the morning session, we had an introduction to the different types of cables concerning their usage and manufacturing techniques. We got a deeper understanding of the manufacturing of wire ropes in particular and also electrical cables. Also, we were introduced to cable harnesses and their importance in terms of the automotive industry. After the lecture session, we were tasked to prepare a presentation on the manufacturing aspects of cable harnesses by reviewing a set of research papers.

The afternoon session began with the importance of virtual prototyping in the context of industrial applications and was followed by a deeper lecture on macroscopic and mesoscopic modeling techniques of cable and cable harnesses. In the afternoon, we were tasked with applying these modeling techniques to a set of problems, and then results were discussed in the last session.

This nwt 7 has indeed been a value-added experience for all novice and experienced participants as it was indeed a quality time spent to discover the scientific approaches in textile engineering and cable harnesses.

Contributed by Indrajeet Patil (ESR 2) and Irfan Haider (ESR 3)